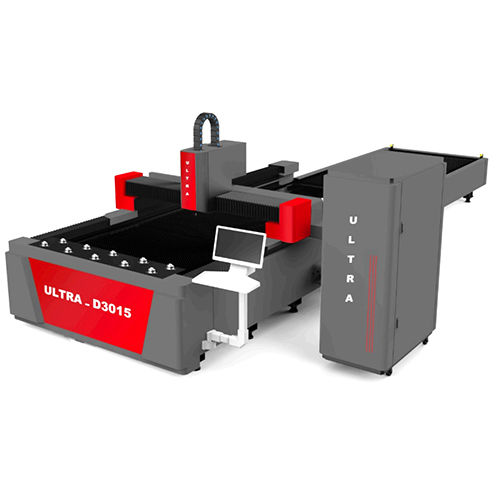

ULTRA D3015 Fiber Laser Metal Cutting Machine

Product Details:

- Phase Three Phase

- Technology Fiber Laser Cutting Technology

- Usage & Applications Sheet Metal Fabrication, Automobile Parts, Electrical Cabinets, Machinery Manufacturing

- Working Area 1500 x 3000 mm Square Millimeter (mm2)

- Power 1000W / 1500W / 2000W (optional) Watt (w)

- Product Type Fiber Laser Metal Cutting Machine

- Laser Type Fiber Laser

- Click to View more

ULTRA D3015 Fiber Laser Metal Cutting Machine Price And Quantity

- 1 Unit

- 3800000 INR/Unit

ULTRA D3015 Fiber Laser Metal Cutting Machine Product Specifications

- Sheet Metal Fabrication, Automobile Parts, Electrical Cabinets, Machinery Manufacturing

- Fiber Laser

- 1000W / 1500W / 2000W (optional) Watt (w)

- Fiber Laser Metal Cutting Machine

- Yes

- White & Blue

- 4600 mm x 2300 mm x 1700 mm Millimeter (mm)

- 0-50 m/min mm/m

- 1500 mm x 3000 mm Square Millimeter (mm2)

- 1500 x 3000 mm Square Millimeter (mm2)

- AI, BMP, DST, DWG, DXF, DXP, LAS, PLT

- CypCut/FSCUT

- High Precision, Fast Speed, Low Maintenance

- 380V/50Hz or 220V/50Hz Watt (w)

- Fiber Laser Cutting Technology

- Water Cooling

- 2800 kg Kilograms (kg)

- Depends on material & thickness Kg/day

- 0.5-16 mm (mild steel), 0.5-8 mm (stainless steel) Millimeter (mm)

- Other

- Three Phase

- Automatic

Product Description

- Outstanding Quality

- Perpetual Innovation

- Satisfying Service

- The medium-power laser cutting machine with the highest precision in China, it can cut small metal bike design with size of half a coin.

- Integrated machine accessories, fast disassembly, left and right drawers collecting saves space.

Specification

|

Working Area |

3000X1500mm / 4000X2000mm |

|

Model Type |

Dual Pallet Exchanger and Open Type |

|

Laser Cutting Head Brand |

Raytools (Switzerland) Autofocus Head BM110 LATEST SERIES |

|

Auto Alignment Sheet (Y or N ) |

YES |

|

Laser Source & Power |

Max. Laser Source (Water Cooled) 1.5KW /2KW/3 KW |

|

Travelling Speed (M/min) |

120m/min |

|

Gentry (Aluminium or Steel casted) |

Aviation Grade Aluminium Gentry |

|

Accuracy repeated & re - positioning |

-/+ 0.03mm |

|

Servo Motors & Drives |

YASKAWA JAPAN Motors & Drives |

|

Linear Guide Rail Brand |

Hiwin (Taiwan) |

|

Electromechanical |

Schneider France |

|

Rack & Pinion Brand & Model |

YYC Taiwan |

|

Water Chiller Brand |

S & A High Cooling Capacity |

|

Speed Reducer Brand |

Shimpo, France |

|

Software |

CYPCUT |

|

CYPCUT Software Version |

FSCUT 2000E Latest Version (BUS CONTROLLER) |

|

Proportional valve |

SMC France / ATC Japan |

|

Auto Lubrication (Y or N ) |

YES |

|

Industrial Computer System Brand |

Windows screen |

|

Control panel Box |

Separate Control Panel for electrical with AC Cooling Cabinet |

|

Acceleration |

1.5G |

|

Machine Power Consumption |

18K W-23K W |

|

Machine Gross Weight |

5780 KG |

High Precision and Fast Performance

The ULTRA D3015 Fiber Laser Metal Cutting Machine is engineered for exacting demands, offering a superior positioning accuracy of 0.03 mm and repeatability of 0.02 mm. Its maximum accelerated speed of 0.8 G and double drive rack & pinion system ensure fast, stable, and efficient cutting. This makes it suitable for high-volume industrial use where precision and speed are both essential.

Flexible Material and Application Range

Designed for versatility, this machine cuts a spectrum of metals, including stainless steel (up to 8 mm), mild steel (up to 16 mm), aluminum, brass, and galvanized steel. It meets the fabrication needs of automotive, electrical, and machinery industries, and supports multiple file formats for various design workflows.

Automated and Safe Operation

Equipped with CNC numerical control and advanced safety systems like a protective enclosure with a viewing window, the ULTRA D3015 enables safe, automated, and computerized cutting. Automatic focusing and water-cooled operation streamline the process, while built-in connectivity (USB and Ethernet) ensures smooth integration and control.

FAQ's of ULTRA D3015 Fiber Laser Metal Cutting Machine:

Q: How does the ULTRA D3015 ensure high cutting precision?

A: The ULTRA D3015 utilizes a double drive rack & pinion system, Taiwan HIWIN linear guide rails, and advanced CNC control, providing a positioning accuracy of 0.03 mm and repeatability of 0.02 mm. These features guarantee precise and consistent cuts, even at high speeds.Q: What materials and thicknesses can this machine cut?

A: This machine can cut stainless steel up to 8 mm, mild steel up to 16 mm, and is also suitable for aluminum, brass, carbon steel, and galvanized steel, making it ideal for a variety of industrial applications.Q: When should I use the automatic focusing feature?

A: The automatic focusing system adjusts the focal point in real-time, which is especially beneficial when switching between materials or thicknesses. This enhances cutting quality and efficiency, eliminating manual adjustments.Q: Where should the ULTRA D3015 be installed for optimal performance?

A: For best results, the machine should be used in a dust-free workshop environment, with temperature control between 0-45C and humidity below 80%, non-condensing, to protect sensitive components and ensure consistent operation.Q: What are the advantages of fiber laser technology in this model?

A: Fiber laser technology delivers high-speed, high-precision cutting with minimal maintenance and a long service life. It provides clean edges, fast operation, and energy efficiency, resulting in lower operational costs over time.Q: How do I connect and control the machine?

A: The ULTRA D3015 offers USB and Ethernet connectivity, allowing you to transfer designs directly. It supports CypCut/FSCUT control software and multiple file formats (such as AI, DWG, DXF), ensuring easy integration with your design workflow.Q: What industries benefit most from using this machine?

A: Industries such as sheet metal fabrication, automobile parts production, machinery manufacturing, and electrical cabinet fabrication can greatly benefit from the ULTRA D3015 due to its versatile cutting capabilities, high precision, and efficient automated processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+