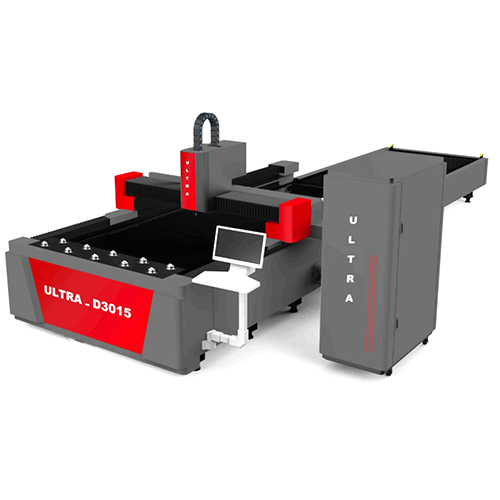

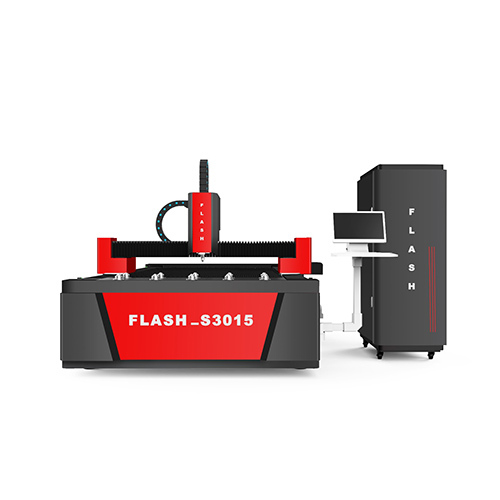

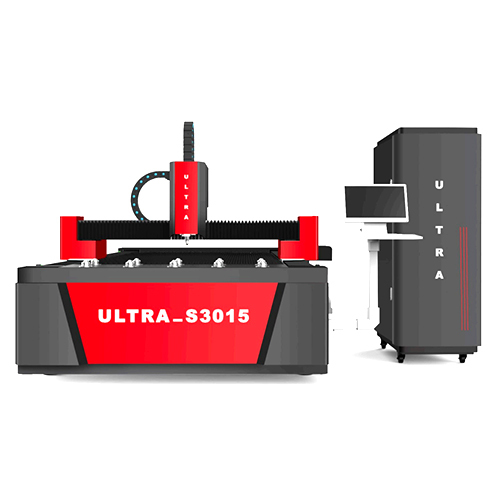

ULTRA TS3015 Fiber Laser Metal Cutting Machine

Product Details:

- Phase 3 Phase

- Technology Fiber Laser Technology

- Power 1500W / 2000W / 3000W / 4000W / 6000W (optional) Watt (w)

- Usage & Applications Sheet Metal Cutting, Engineering, Automotive, Machinery, Electrical Enclosures

- Working Area 3000 mm x 1500 mm Square Millimeter (mm2)

- Product Type Metal Cutting Machine

- Laser Type Fiber Laser

- Click to View more

ULTRA TS3015 Fiber Laser Metal Cutting Machine Price And Quantity

- 1 Unit

- 280000 INR/Unit

ULTRA TS3015 Fiber Laser Metal Cutting Machine Product Specifications

- CypCut Control System

- 3 Phase

- AI, DXF, PLT, BMP, DST, DXP

- 4500 mm x 2300 mm x 1700 mm Millimeter (mm)

- Other

- Fiber Laser Technology

- Automatic

- 3000 mm x 1500 mm Square Millimeter (mm2)

- 3300 kg (Approximate) Kilograms (kg)

- Metal Cutting Machine

- 0.5-20 mm (varies by material and power) Millimeter (mm)

- 1500W / 2000W / 3000W / 4000W / 6000W (optional) Watt (w)

- High Precision, Low Maintenance, Stable Performance, Energy Efficient

- Fiber Laser

- Water Cooling

- up to 35 m/min mm/m

- Yes

- Standard (Customizable as per request)

- 380V / 50Hz, 3 Phase Volt (v)

- Continuous / High Production Tons/year

- Sheet Metal Cutting, Engineering, Automotive, Machinery, Electrical Enclosures

- 3000 mm x 1500 mm Square Millimeter (mm2)

Product Description

- Outstanding Quality

- Perpetual Innovation

- Satisfying Service

- The medium-power laser cutting machine with the highest precision in China, it can cut small metal bike design with size of half a coin.

- Integrated machine accessories, fast disassembly, left and right drawers collecting saves space.

Specification

|

Working Area |

3000X1500mm / 4000X2000mm |

|

Model Type |

Single Table with 3 mtr. Side Rotary Attachment |

|

Laser Cutting Head Brand |

Raytools (Switzerland) Autofocus Head BM110 LATEST SERIES |

|

Auto Alignment Sheet (Y or N ) |

YES |

|

Laser Source & Power |

Max. Laser Source (Water Cooled) 1.5KW /2KW/3 KW |

|

Travelling Speed (M/min) |

120m/min |

|

Gentry (Aluminium or Steel casted) |

Aviation Grade Aluminium Gentry |

|

Accuracy repeated & re - positioning |

-/+0.03mm |

|

Servo Motors & Drives |

YASKAWA JAPAN Motors & Drives |

|

Linear Guide Rail Brand |

Hiwin (Taiwan) |

|

Electromechanical |

Schneider France |

|

Rack & Pinion Brand & Model |

YYC Taiwan |

|

Water Chiller Brand |

S & A High Cooling Capacity |

|

Speed Reducer Brand |

Shimpo, France |

|

Software |

CYPCUT |

|

CYPCUT Software Version |

FSCUT 2000E Latest Version (BUS CONTROLLER) |

|

Proportional valve |

SMC France / ATC Japan |

|

Auto Lubrication (Y or N ) |

YES |

|

Industrial Computer System Brand |

Windows screen |

|

Control panel Box |

Separate Control Panel for electrical with AC Cooling Cabinet |

|

Acceleration |

1.5G |

|

Machine Power Consumption |

18K W-23K W |

|

Machine Gross Weight |

4850 KG |

Precision Engineering for Superior Results

Achieve unmatched accuracy with the ULTRA TS3015 Fiber Laser Metal Cutting Machine. Its cutting-edge design features advanced drive and control components that allow for consistent, clean cuts across a wide range of metals. The auto focusing function and automatic lens protection system further enhance performance and reduce downtime, resulting in stable, high-quality outputs every cycle.

Versatile and High-Performance Application

This fiber laser machine adapts easily to different production needs with its selectable laser power, table types, and optional tube cutting, chiller, and compressor units. Capable of handling a variety of graphic formats and file transfer methods, it integrates smoothly into engineering, automotive, electrical, and machinery workflows for efficient, precise sheet metal processing.

User-Friendly Interface and Safer Operations

Operations are streamlined with the touchscreen HMI panel powered by the CypCut Control System, offering intuitive controls for experienced and new operators alike. Optional safety features such as a fully enclosed protective cover and smoke filtering system ensure a secure working environment, while the modular construction allows for straightforward maintenance.

FAQ's of ULTRA TS3015 Fiber Laser Metal Cutting Machine:

Q: How does the ULTRA TS3015 ensure high-precision metal cutting?

A: The ULTRA TS3015 achieves high-precision cutting with its advanced Double Servo Motor drive system, positioning accuracy of 0.02 mm, and auto focusing mechanism. The CypCut CNC control system and automatic lens protection further help maintain precision and consistency during production.Q: What materials and thicknesses can the machine cut?

A: This fiber laser cutting machine is designed for materials such as carbon steel, stainless steel, aluminum, brass, and copper. It can accurately cut thicknesses ranging from 0.5 mm up to 20 mm, depending on material type and selected laser power.Q: When should I use the exchange table or single table option?

A: The choice between exchange table and single table depends on your production needs. Exchange tables are ideal for continuous, high-volume jobs, allowing simultaneous cutting and material loading/unloading. Single tables are suitable for lower volume or single-operation cutting tasks.Q: Where can the ULTRA TS3015 be installed for optimal performance?

A: For optimal results, the machine should be installed in a well-ventilated environment, within the temperature range of 5-40C and humidity below 95% (non-condensing). Adequate space is also needed to accommodate its dimensions and ensure safe operation and maintenance access.Q: What is the process for transferring cutting files to the machine?

A: You can transfer graphic cutting files using USB, LAN, or Ethernet. The machine supports various industry-standard formats such as AI, DXF, PLT, BMP, DST, and DXP, streamlining integration into your existing CAD/CAM workflow.Q: How does the machine maintain lens protection and reduce maintenance needs?

A: The ULTRA TS3015 features an automatic lens protection system, which shields the lens from contamination and damage during operation. This reduces downtime, extends component lifespan, and minimizes maintenance requirements.Q: What are the main benefits of using the ULTRA TS3015 fiber laser cutting machine?

A: Key benefits include exceptional cutting precision, high-speed production, energy-efficient operation, easy-to-use touchscreen controls, and versatile compatibility with a range of materials and graphic formats. Optional features enhance safety and productivity, making it a robust choice for demanding industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+